Your Mazda’s ABS warning light just popped on, and you’re wondering what’s up with the Mazda ABS pump and sensors. It’s easy to get worried, but often, these issues are fixable. This guide breaks down what your ABS system does, why those lights come on, and how you can start figuring out what’s going on with your Mazda ABS pump and sensors without losing your mind.

Key Takeaways

- The ABS module is the ‘brain’ of your anti-lock braking system, working with wheel speed sensors and the ABS pump to prevent wheel lockup.

- Common signs of trouble include the ABS warning light, traction control issues, and weird speedometer readings.

- Start troubleshooting by checking the brake fluid, inspecting wires and fuses, and then move to more advanced checks like using an OBD-II scanner.

- Faulty wheel speed sensors, damaged tone rings, or issues with the ABS pump itself are frequent culprits behind ABS problems.

- Regular maintenance, like keeping brake fluid clean and protecting sensors, can help prevent future issues with your Mazda ABS pump and sensors.

Understanding Your Mazda ABS Pump and Sensors

So, you’ve got a little light on your dash that says ABS, and maybe your traction control is acting up too. It’s easy to get worried, but most of the time, it’s something you can figure out. Your Mazda’s Anti-lock Braking System, or ABS, is basically a smart system designed to help you keep control when you have to slam on the brakes. It stops your wheels from locking up, which lets you steer around obstacles instead of just sliding straight ahead. Pretty neat, right?

What Is An ABS Module?

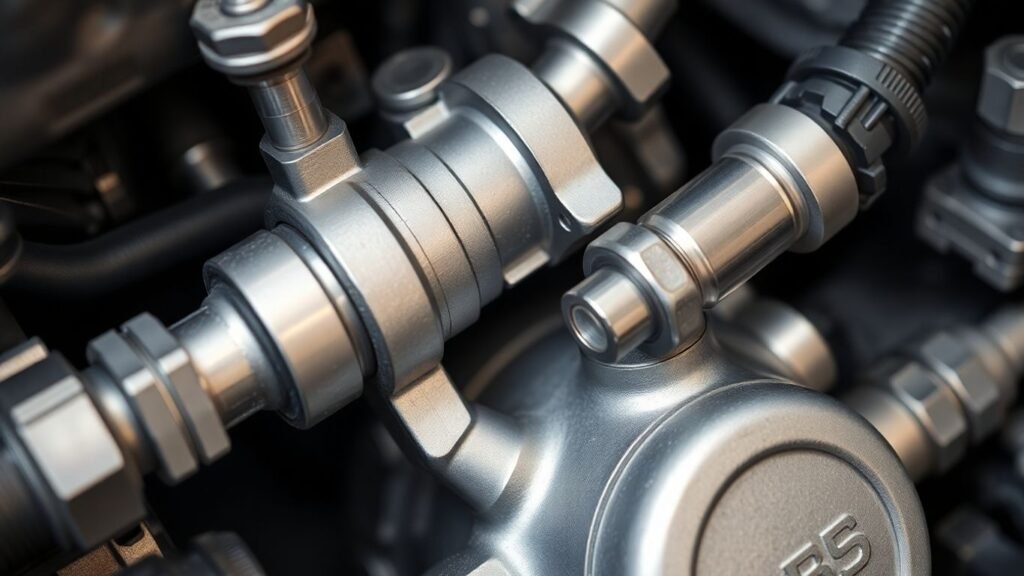

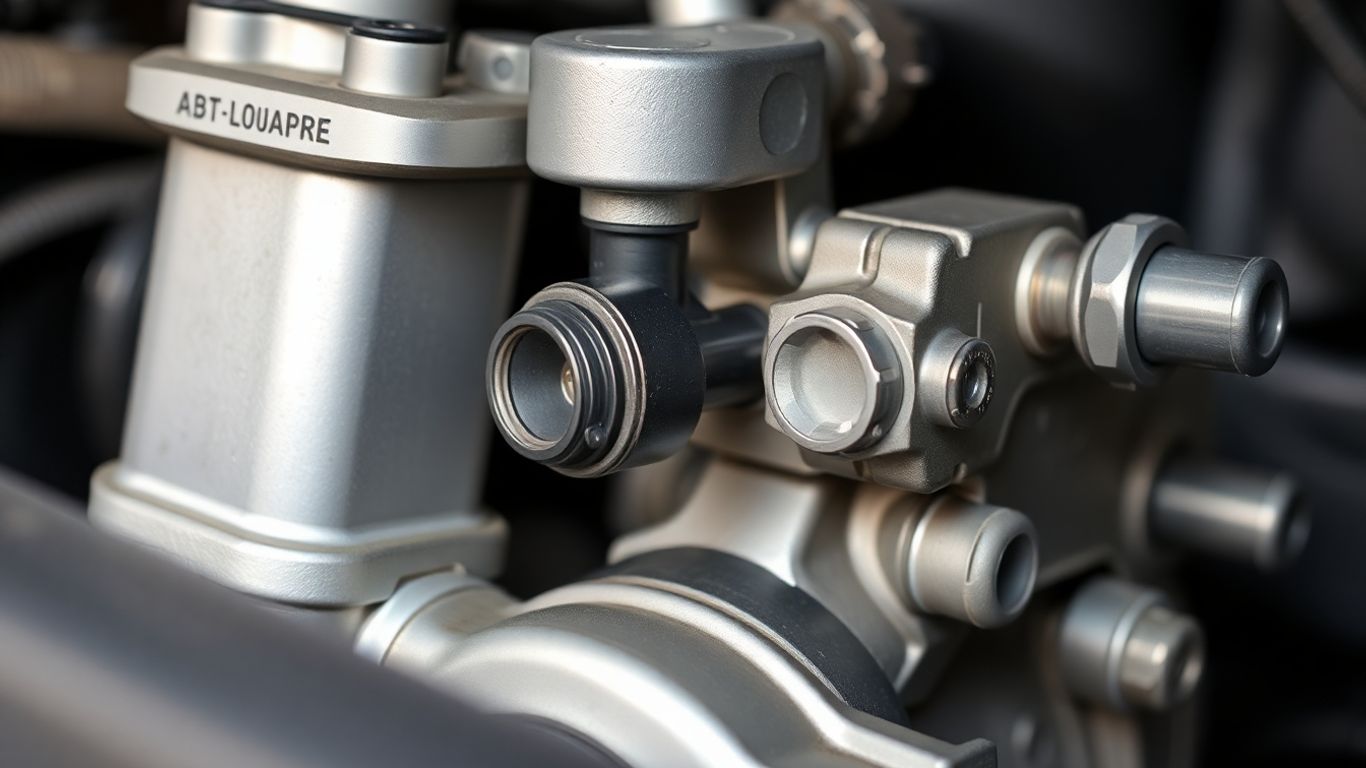

Think of the ABS module as the brain of the whole operation. It’s a computer that’s constantly getting information from different parts of your car, especially the wheels. When it senses a wheel is about to lock up during braking, it tells the ABS pump and valves to do their thing. This module is usually tucked away somewhere, sometimes near the master cylinder or even down on the frame rail, and it’s connected to everything with a bunch of wires and brake lines. It’s the central hub that makes all the decisions.

How Your Mazda ABS System Works

When you hit the brakes, the system normally sends hydraulic pressure to all your wheels. But if the ABS module detects one or more wheels slowing down way too fast – meaning they’re about to lock – it intervenes. It rapidly pulses the brake pressure to that specific wheel, releasing and reapplying it many times a second. This allows the wheel to keep rotating, giving you better steering control and shorter stopping distances on most surfaces. You might feel a pulsing in the brake pedal or hear some grinding noises when this happens; that’s normal ABS operation.

The ABS system works by monitoring wheel speed and adjusting brake pressure. If a wheel locks, the system momentarily reduces pressure to allow it to spin again, preventing a skid. This cycle repeats rapidly until you release the brakes or the wheels regain traction.

The Role Of Wheel Speed Sensors

These little guys are super important. You’ve got one at each wheel, and their job is to tell the ABS module how fast each wheel is spinning. They work with a toothed ring, often called a tone ring or reluctor ring, that’s attached to the wheel hub or axle. As the wheel turns, the teeth on the ring pass by the sensor, creating an electrical signal. The ABS module reads these signals. If one sensor stops sending a signal, or sends a signal that’s way off from the others, the module knows there’s a problem. Sometimes these sensors just get dirty with brake dust or metal shavings, or the tone ring might get damaged. It’s often the first place to look when the ABS light comes on.

Common Mazda ABS Warning Light Triggers

So, you’ve noticed that little ABS light has popped on your dashboard. It’s easy to ignore, but it’s actually telling you something important about your Mazda’s braking system. This light isn’t just for show; it indicates a problem that could affect your car’s ability to stop safely.

When the ABS warning light illuminates, it usually means the system has detected a fault. This could be anything from a simple sensor issue to a more complex problem with the ABS module itself. Sometimes, other warning lights might come on too, like the traction control or stability control lights. It’s not uncommon for the speedometer to act up, showing weird readings or just stopping altogether, especially if the same wheel speed sensor is involved.

It’s really important to remember that even if the ABS light is on, your regular brakes should still work. You just won’t have that anti-lock feature to prevent your wheels from locking up during hard stops. So, if this happens, just be extra careful, give yourself more space from the car in front, and try not to brake too suddenly.

Here’s a quick look at what might be going on:

| Symptom | Possible Cause |

|---|---|

| Illuminated ABS Warning Light | Faulty wheel speed sensor, low brake fluid, blown fuse, ABS module issue |

| Traction Control Malfunctions | Often linked to ABS sensor or module problems |

| Speedometer Issues | Typically a faulty wheel speed sensor |

Troubleshooting Mazda ABS Pump and Sensor Issues

So, that ABS light pops on your dash, huh? It’s never a fun sight, but don’t panic just yet. Most of the time, it’s something you can figure out without a trip to the dealership. We’re going to walk through some basic checks you can do yourself to get a better idea of what’s going on with your Mazda’s anti-lock braking system.

Initial Diagnostic Steps For Your Mazda

Before you start pulling things apart, let’s cover the easy stuff. Sometimes, a simple restart can clear a temporary glitch. If the light stays on, it’s time to get a little more hands-on. The first thing to check is the brake fluid level. Low fluid can throw off the whole system. Make sure your Mazda is on a level surface and check the reservoir. If it’s low, top it off with the correct type of fluid specified in your owner’s manual. Also, take a look at the fluid itself. Is it dark or dirty? That could be a sign of bigger issues down the road.

Checking Brake Fluid Level And Condition

This is pretty straightforward. Locate the brake fluid reservoir under the hood – it’s usually a translucent plastic container with a cap marked with a brake symbol. Check the fluid level against the MIN and MAX lines on the side. If it’s below MIN, add the recommended fluid type. While you’re there, look at the fluid’s color. Fresh brake fluid is typically clear or slightly amber. If it looks dark brown or black, it’s contaminated and likely needs a full brake fluid flush. This isn’t just about the ABS; it affects your regular braking too.

Inspecting Wiring And Connectors

This is where things can get a bit more involved. The ABS system relies on a network of wires and sensors. You’ll want to visually inspect the wiring harnesses that run to your wheel speed sensors and the ABS module itself. Look for any obvious signs of damage, like frayed wires, cuts, or melted insulation. Pay close attention to the connectors; make sure they are clean, dry, and securely plugged in. Sometimes, corrosion or dirt can get into these connections and cause communication problems. A loose connector is an easy fix, but damaged wires might need more attention.

Verifying ABS System Fuses

Your ABS system has its own set of fuses, and a blown fuse is a common culprit for a non-functioning system. You’ll need to consult your owner’s manual to find the fuse box locations (there might be more than one) and identify which fuses are for the ABS. Once you find them, pull each fuse out and hold it up to the light. If you see a broken filament inside, the fuse is blown and needs to be replaced with one of the exact same amperage rating. Don’t just guess on the amperage; using the wrong one can cause damage.

Remember, the ABS is a safety feature. If you’re not comfortable with any of these checks, or if the problem seems more complex, it’s always best to have a qualified mechanic take a look. Trying to fix things without the right knowledge could make the problem worse or even create a safety hazard.

| Component | Potential Issue | What to Look For |

|---|---|---|

| Brake Fluid | Low level, contamination | Reservoir level below MIN, dark or murky fluid |

| Wiring Harnesses | Damage, corrosion, loose connections | Frayed wires, cuts, melted insulation, corroded pins, loose connectors |

| Fuses | Blown fuse | Broken filament inside the fuse |

| Wheel Speed Sensor | Dirt, damage, loose connection | Debris on sensor or reluctor ring, visible damage to sensor or wiring, loose fit |

| ABS Module | Electrical fault, internal damage | Corrosion on module connections, no response to diagnostic tools (advanced check) |

Advanced Diagnostics For Mazda ABS Systems

Using An OBD-II Scanner For ABS Codes

So, you’ve checked the basics and the ABS light is still on. Time to get a bit more technical. Hooking up an OBD-II scanner is your next logical step. This little gadget plugs into a port usually found under your dashboard and can read trouble codes stored in your car’s computer, including the ABS module. These codes are like cryptic messages from your car, pointing you towards the problem area. For example, a code like C0035 might tell you there’s an issue with the left front wheel speed sensor circuit. It’s not always a direct "replace this part" message, but it narrows down the possibilities significantly. You can find these scanners online or at auto parts stores, and many can read ABS codes, not just engine codes.

Testing Wheel Speed Sensor Resistance

Once you have a code pointing to a specific wheel speed sensor, or if you suspect one is acting up, you’ll want to test its resistance. You’ll need a multimeter for this. First, locate the sensor and its connector. Disconnect it and set your multimeter to measure resistance (ohms). Then, place the probes on the sensor’s terminals. The resistance value should fall within a specific range, which you can usually find in your Mazda’s service manual. If the resistance is too high, too low, or infinite (meaning an open circuit), the sensor is likely bad and needs replacing. It’s a good idea to test all four sensors to compare readings and make sure they’re all within spec.

Inspecting Tone Rings For Damage

Wheel speed sensors work by reading a toothed ring, called a tone ring or reluctor ring, that spins with the wheel hub. If this ring is damaged, bent, or has debris stuck in its teeth, it can send faulty signals to the ABS module, or no signal at all. You’ll need to get the wheel off the ground and visually inspect the tone ring. Look for any cracks, missing teeth, or foreign material. Sometimes, just cleaning off dirt and grime is enough to fix the problem. If the ring is physically damaged, it will need to be replaced. This can be a bit tricky, as it’s often pressed onto the hub or part of the CV axle.

Checking Power And Ground To The ABS Module

If the OBD-II scanner can’t communicate with the ABS module at all, or if you’ve replaced a sensor and the light is still on, the problem might be with the module itself or its power supply. You’ll need to locate the ABS module, which is usually part of the hydraulic unit under the hood. Check the wiring harness connected to it. Using your multimeter, verify that the module is receiving proper voltage from the battery (power) and has a good connection to the car’s chassis (ground). A loose wire, corroded terminal, or blown fuse in the power supply circuit can cause the entire system to fail. This step requires a bit more confidence with electrical testing, so if you’re not comfortable, it’s best left to a professional.

Sometimes, the ABS module itself can fail internally. This is less common than sensor issues but can happen. If all other checks come back clean, and you’re still experiencing problems, the module might be the culprit. Professional repair services can often fix these modules, which can be cheaper than buying a new one.

| Component Tested | Typical Resistance Range (Ohms) | Notes |

|---|---|---|

| Wheel Speed Sensor | 1000 – 2000 | Varies by model; check service manual |

| ABS Module Power Supply | ~12 Volts DC | Check with ignition on |

| ABS Module Ground | < 1 Ohm | Ensure clean connection to chassis |

Specific Mazda ABS Faults And Solutions

Sometimes, your Mazda’s ABS system throws a fit, and it’s not always obvious why. Let’s break down some common problems and what might be going on.

ABS Light On: Possible Causes and Repairs

An illuminated ABS warning light is your car’s way of saying something’s up. It could be as simple as a faulty wheel speed sensor not sending the right signals, or maybe the brake fluid is just too low. Sometimes, it’s just a blown fuse in the ABS circuit.

The fix usually involves identifying the specific fault code with a scanner, then addressing the root cause, whether that’s replacing a sensor, topping up brake fluid, or swapping out a fuse.

Random ABS Activation: Diagnosis and Fixes

Ever been braking normally, and suddenly the ABS kicks in like you’re in a panic stop? That’s unsettling. This can happen if the "tone rings" (those toothed rings on the axle that the speed sensors read) are damaged or have debris stuck to them. It can also occur if a wheel speed sensor is slightly out of alignment. The system gets confused by inconsistent speed readings and thinks it needs to intervene.

No ABS Function: Identifying the Problem

If your ABS light is on and you suspect the system isn’t working at all, it’s a serious concern. This could point to a bigger issue, like a failed ABS module itself or a problem with the ABS pump motor. The module is the brain of the operation, and the pump is what actually applies pressure to the brakes. If either of these goes kaput, you lose that anti-lock capability.

Grinding Noises During Braking

While ABS can sometimes make a pulsing or grinding sound during an emergency stop, a constant grinding noise during normal braking isn’t usually a good sign. This could indicate debris caught near a wheel speed sensor, or it might be a sign of a failing wheel bearing that’s affecting the sensor’s ability to read the tone ring properly.

It’s important to remember that the ABS system is a safety feature. If you’re experiencing any of these issues, especially if the ABS light is on or you hear unusual noises, it’s best to get it checked out by a qualified mechanic sooner rather than later. Driving without fully functional ABS can be risky, particularly in sudden braking situations.

| Symptom | Potential Cause(s) | Likely Repair(s) |

|---|---|---|

| ABS light is on | Faulty wheel speed sensor, low brake fluid, fuse | Replace sensor, top up fluid, replace fuse |

| ABS activates randomly | Damaged tone ring, misaligned sensor | Replace tone ring, realign sensor |

| No ABS function | Failed ABS module, pump motor failure | Module testing/replacement, pump motor repair/replace |

| Grinding noise (normal braking) | Debris near sensor, failing wheel bearing | Clean sensor area, replace wheel bearing |

Mazda ABS Sensor Replacement Guide

Locating Your Mazda’s ABS Sensors

Finding the ABS sensors on your Mazda isn’t always straightforward. They’re usually tucked away near the wheel hubs, often behind brake components like calipers or dust shields, to keep them protected from road grime and impacts. The easiest way to find them is to follow the wire that comes from the sensor; it usually leads back to a connector somewhere on the chassis or near the brake lines. Sometimes, they’re integrated directly into the hub assembly or even the brake caliper bracket. Don’t be surprised if you have to remove a wheel, and possibly even the brake rotor, to get a clear view. They’re designed to be out of the way, which is good for protection but makes them a bit of a scavenger hunt when it’s time for maintenance.

Steps For Replacing A Faulty ABS Sensor

So, you’ve figured out a wheel speed sensor is giving you grief. The first thing to do is loosen the lug nuts on the affected wheel while the car is still on the ground. Then, use your jack and jack stands to lift the vehicle securely – always refer to your owner’s manual for the correct jacking points. Once the wheel is off, you’ll likely need to remove the brake caliper and rotor to get to the sensor. It’s usually held in place by a single bolt. Unplug the electrical connector, remove that bolt, and carefully pull the old sensor out. Clean the area where the sensor sits, especially around the reluctor ring (the toothed wheel it reads). Then, install the new sensor, making sure it’s seated properly. Reinstall the bolt, reconnect the wiring, and put the brake rotor and caliper back on. Don’t forget to torque everything to spec. Put the wheel back on, lower the car, and tighten the lug nuts. Finally, clear any ABS codes with your scanner and take it for a test drive to make sure the light stays off.

Cleaning Sensors And Reluctor Rings

Sometimes, a sensor isn’t actually bad; it’s just dirty or the reluctor ring it reads is gunked up. This is especially common if you drive on dusty or muddy roads. You’ll want to carefully clean the sensor tip itself with a soft cloth and some brake cleaner. For the reluctor ring, which is that toothed wheel near the sensor, use a brush or compressed air to remove any accumulated metal shavings or dirt. A clean reluctor ring and sensor tip are vital for the ABS system to get an accurate reading. If you find any damage, like bent teeth on the ring, it’s usually best to replace the ring too, which can sometimes be a more involved job.

It’s easy to overlook the simple stuff when troubleshooting ABS issues. Before diving into sensor replacement, double-check that your brake fluid is clean and at the correct level. Old, dirty fluid or low fluid can sometimes trigger ABS warning lights, making you think you have a more complex problem than you actually do. It’s a quick check that can save you a lot of time and hassle.

Preventative Maintenance For Your Mazda ABS

Taking care of your Mazda’s Anti-lock Braking System (ABS) doesn’t have to be a huge chore. A little bit of regular attention can go a long way in keeping this important safety feature working right. It’s not just about fixing things when they break; it’s about trying to stop them from breaking in the first place, you know?

Regular System Inspections

Think of this as a quick once-over. When you’re doing your regular oil changes or tire rotations, take a few minutes to just look around the ABS components. Are there any obvious signs of damage? Any loose wires hanging around? It’s amazing what you can spot just by giving things a visual check. Catching a small issue early can save you a lot of hassle down the road. Sometimes, a wire might get snagged or a connector might loosen up from vibrations. A quick look can prevent a bigger problem.

Maintaining Clean Brake Fluid

Your brake fluid is like the lifeblood of your braking system, ABS included. Over time, it can get dirty or absorb moisture. This isn’t good. Dirty fluid can gum up the works inside the ABS module and other brake parts, leading to premature wear and tear. Most manufacturers suggest flushing and replacing your brake fluid every two to three years. It’s a relatively inexpensive service that can really help protect your ABS system from internal damage. Don’t wait until your brakes feel spongy; that’s often a sign the fluid is past its prime.

Protecting Sensors From Debris

Those little wheel speed sensors and their associated tone rings are pretty important, right? They’re often located near the wheel hubs, which means they can get exposed to road grime, salt, and other gunk. While they’re designed to be tough, a buildup of dirt or debris can sometimes interfere with their readings. When you’re cleaning your wheels, give the visible parts of the sensors and the area around them a gentle wipe-down. You don’t need to go crazy, but keeping them reasonably clean can help ensure they’re sending accurate signals to the ABS computer. If you live in an area with a lot of salt or dirt, this becomes even more important.

Sometimes, the simplest maintenance steps are overlooked. Just being aware of your ABS system and giving it a quick look during routine service can make a big difference in its long-term reliability. It’s not rocket science, just good old-fashioned car care.

| Component | Recommended Action | Frequency |

|---|---|---|

| Brake Fluid | Check level and condition; flush and replace | Every 2-3 years |

| ABS Wiring/Connectors | Visual inspection for damage or looseness | During routine service |

| Wheel Speed Sensors | Gentle cleaning of visible sensor areas and rings | During wheel cleaning |

Wrapping It Up

So, dealing with your Mazda’s ABS system can seem a bit daunting, especially with all those sensors and that pump. But hey, a lot of the time, it’s just a loose wire, some dirty gunk on a sensor, or maybe a fuse that blew. We’ve gone over the basics, like checking fluid and fuses, and then got into the more involved stuff like using a scanner. Remember, your brakes are super important for safety. If you’re ever feeling unsure about what’s going on, or if you’ve tried the simple fixes and the light is still on, it’s always a good idea to have a mechanic take a look. They’ve got the fancy tools and know-how to get it sorted out right. Drive safe out there!